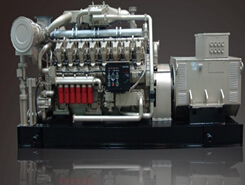

瓦斯發(fā)電機(jī)組的偶件損壞原因及保養(yǎng)

今天為大家講解一下瓦斯發(fā)電機(jī)組偶件損壞的根本原因及保養(yǎng),讓大家平??梢宰鳛閰⒖际褂?,對使用設(shè)備進(jìn)行安全工作有幫助。

Today, I will explain to you the root cause and maintenance of the damage of even parts of the gas generator set, so that you can use it as a reference at ordinary times, which is helpful for the safe work of the equipment.

瓦斯發(fā)電機(jī)組偶件損壞的根本原因除產(chǎn)品質(zhì)量問題外,主要是對機(jī)器使用不當(dāng),維修保養(yǎng)不及時、不正確造成的。下面談幾點延長偶件使用壽命采取的措施,以供參考。

In addition to the product quality problems, the root causes of the damage of the couple parts of the gas generator set are mainly caused by the improper use of the machine, the untimely and incorrect maintenance. Here are some measures taken to prolong the service life of the couple for reference.

、嚴(yán)格執(zhí)行燃油沉淀過濾制度,加注的瓦斯少應(yīng)經(jīng)48小時沉淀后才能取用。使用的瓦斯應(yīng)符合季節(jié)規(guī)定的標(biāo)準(zhǔn)型號。加油工具要清潔專用。加油和存油的地方也應(yīng)清潔,以免臟物混入燃油而加速偶件的磨損,降低偶件使用壽命。

Strictly implement the fuel oil sedimentation and filtration system, and the gas injected should be used after 48 hours of sedimentation. The gas used shall conform to the standard model specified in the season. The refueling tools should be clean and special. The place where the oil is filled and stored should also be clean, so as to prevent dirt from mixing with the fuel, which will accelerate the wear of the coupling and reduce the service life of the coupling.

制定嚴(yán)格的技術(shù)維護(hù)保養(yǎng)規(guī)范,燃油濾清器工作100小時,油箱工作500小時各清洗一次,若發(fā)現(xiàn)濾芯破損失效應(yīng)及時更換,不得將其拆除而采用直流式供油。偶件在正常工作條件下工作500小時應(yīng)拆卸檢查一次。

Formulate strict technical maintenance specifications. Clean the fuel filter once every 100 hours and the oil tank once every 500 hours. If the filter element is found to be broken, replace it in time. Do not remove it and use direct flow oil supply. Even parts should be disassembled and inspected once after working for 500 hours under normal working conditions.

在拆卸檢查時要保證場所、手、工具和清洗油清潔,以免偶件受污染。在拆卸操作時不得亂敲亂打,在清洗時不要亂堆亂放,不應(yīng)和其它非偶件在一起盆洗,以免碰傷、擦傷。

During disassembly and inspection, ensure that the place, hands, tools and cleaning oil are clean to prevent even parts from being polluted. It is not allowed to knock and beat randomly during the disassembly operation, and do not pile and place randomly during the cleaning. It is not allowed to wash together with other non matching parts, so as to avoid bruises and scratches.

在裝配時不得隨意改變裝配位置而達(dá)到某些不符合機(jī)器工作要求的目的。在裝出油閥緊座和油嘴緊帽時,應(yīng)按規(guī)定力矩擰緊,以保證裝配后的噴油器和噴油泵技術(shù)狀態(tài)的良好。

During assembly, it is not allowed to change the assembly position at will to achieve some purposes that do not meet the working requirements of the machine. When installing the tight seat of the oil outlet valve and the tight cap of the oil nozzle, it should be tightened according to the specified torque to ensure that the assembled fuel injector and fuel injection pump are in good technical condition.

除上述要求外,還應(yīng)提高對偶件的認(rèn)識,弄懂偶件的結(jié)構(gòu)特性和工作原理,加強(qiáng)和提高對偶件的維護(hù)保養(yǎng)、操作使用,做到無故障時不隨意調(diào)整,維護(hù)使用時不隨意拆卸,維修檢查時不亂敲亂打,清洗保養(yǎng)時不亂擦亂碰,裝配調(diào)整時不亂改亂擰,一切按規(guī)范技術(shù)要求進(jìn)行,以達(dá)到延長其使用壽命的目的。更多的注意事項就來我們網(wǎng)站http://m.elmasticar.com咨詢愛吧。

In addition to the above requirements, it is also necessary to improve the understanding of the dual parts, understand the structural characteristics and working principle of the dual parts, strengthen and improve the maintenance, operation and use of the dual parts, and ensure that they are not adjusted at will when there is no fault, not disassembled at will during maintenance and use, not knocked and knocked at random during maintenance and inspection, not rubbed and touched at random during cleaning and maintenance, and not changed and twisted at random during assembly and adjustment, all in accordance with the technical requirements of the specification, In order to prolong its service life. Come to our website for more precautions http://m.elmasticar.com Consult love.

在線咨詢

在線咨詢 官方二維碼

官方二維碼

當(dāng)前位置:

當(dāng)前位置: 2022.08.04

2022.08.04